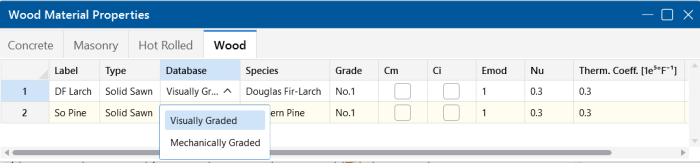

Wood - Database

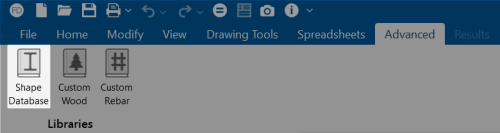

The Wood Database may be accessed by clicking the Shape Database button on the Advanced tab of the ribbon and then clicking the Wood tab of the Shape Database dialog.

Click on image to enlarge it

Click on image to enlarge it

Wood Material/Shape Selection

Unlike any other material, the design properties for wood members depends both on the material selection, as well as the shape selection. Therefore, the Wood tab of the Shape Selection database contains shape and material selections.

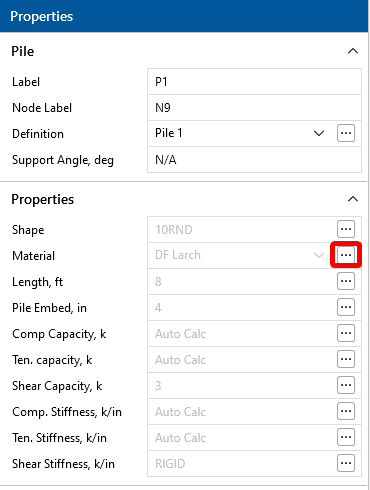

Material Selection

The Material Selection menu reads in material options that are currently listed on the Wood tab of your Materials Spreadsheet. You may select one of these existing materials, or click on the  (ellipsis) button to open the Review or Change Material dialog, which will allow you to add in a new material, or edit an existing material without having to go to the Materials Spreadsheet.

(ellipsis) button to open the Review or Change Material dialog, which will allow you to add in a new material, or edit an existing material without having to go to the Materials Spreadsheet.

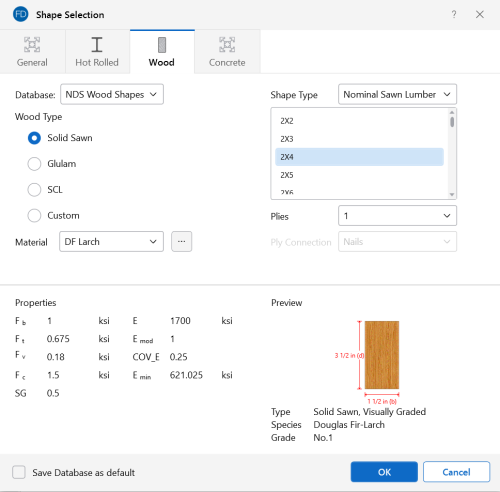

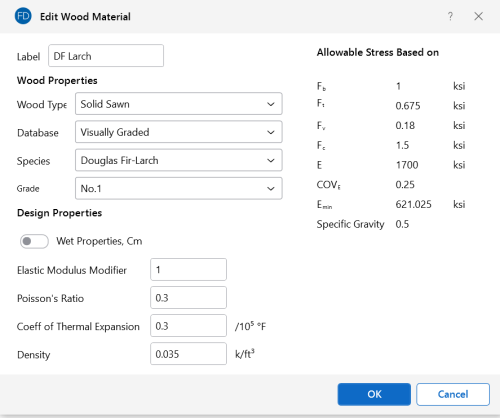

Create/Edit Wood Material dialog

The Create/Edit Wood Material dialog allows you to create or edit a material that will then be automatically added to your Materials Spreadsheet. This allows you to enter/select this information directly from the Draw Members Property panel without having to first manually enter the information in the Materials Spreadsheet.

Click on image to enlarge it

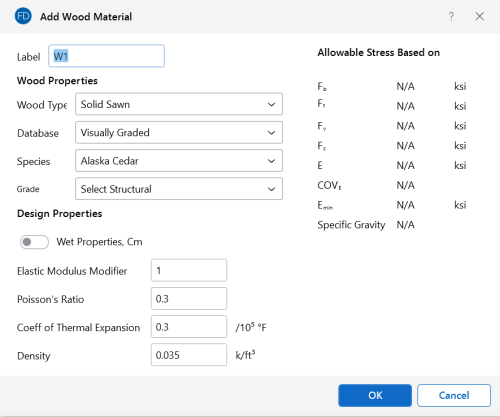

To create a new custom wood material, first choose Custom from the Wood Type drop-down. Then, click on the Add button to manually enter the design values for a new custom wood material. This information will then be automatically saved to the Custom Wood Species Spreadsheet.

Click on image to enlarge it

Size Selection

Currently there are two ways to define a member size. In the Shape Type drop-down, the options available are from either the defined list of Nominal Sawn Lumber sizes, or by using the Net Rectangular/Round option (typically referred to as Full Sawn).

- The Nominal Sawn Lumber option will populate a list of nominal size shapes for the NDS design code and a list of net sized shapes for the CSA O86 design code. When the NDS design code is chosen, the program will automatically reduce the shape properties to their net sizes. If the CSA O86 design code is selected, a list of actual metric sizes will be shown.

- The Net Rectangular or Net Round option will allow you to manually enter any dressed size that you like.

- Rectangular imperial full sawn (as opposed to nominal dimensions) shapes will be designated with a "FS" suffix. You may also use this nomenclature to type the size directly into the spreadsheet. For example, a 7.25"x12" net rectangular member can be typed in as "7.25x12FS".

- Rectangular metric full sawn (as opposed to nominal dimensions) rectangular shapes will be designated with a "MFS" suffix. You may also use this nomenclature to type the size directly into the spreadsheet. For example, a 184mmx305mm net rectangular member can be typed in as "184x305MFS".

- Round imperial shapes will be designated with a "RND" suffix. You many also use this nomenclature to type the size directly into the spreadsheet. For example, a 10" net round member can be typed as "10RND".

- Round metric shapes will be designated with a "MRND" suffix. You many also use this nomenclature to type the size directly into the spreadsheet. For example, a 254mm net round member can be typed as "254MRND".

- Multiple-ply lumber is assumed to be fastened sufficiently to achieve full composite behavior between plies. Therefore, a two-ply member will have eight times greater minor-axis flexural stiffness than a single ply member (as opposed to double the stiffness).

- If using multiple plies, there is a Ply Connection drop-down menu. If the bolted option is selected it is assumed the plies are bolted together. This affects the Kf value from section 15.3.2 of the NDS 2005/2008, 2012, 2015, 2018 and 2024. If you define the multi-ply section as bolted a "B" (or "MB" for metric sizes) will appear after the shape name.

View Design Properties

Once you have selected the appropriate member size and material, you can view the un-adjusted wood design values (Fb, Fv, Ft, etc.) for the selected options in the Properties table at the bottom of the dialog. The final adjusted values (Fb', Fv',Ft', etc.) will then be displayed after solution in the Detail Reports.

Wood Database Limitations

Round Shapes

Per section 3.7.3 of the NDS, the design of a round cross section shall be based on the design calculations for a square shape with the same cross-sectional area. Therefore, the moment of inertia values will be calculated per the equivalent square shape, not the round cross section. However, the section modulus value, S, is calculated per the actual round shape.

Glulam Databases

The program includes five tables of available glulam materials: NDS Tables 5A - 5D and CSA O86 Table 6.3. The values in NDS tables 5B & 5D depend on the number of laminations in the glulam. Therefore, you will see three listings (2 Laminations, 3 Laminations, or 4 Laminations) for each material. If you have a custom material that is not available from these lists, you can always enter your appropriate design values as a Custom Wood Material for use in your model.

- The design values used per NDS tables 5B & 5D take into account footnote #1 to reduce the reference shear design value Fvy depending on the number of lamintations.

- None of the other footnotes in either of these tables is taken into account.

Mechanically Graded Lumber

Mechanically graded lumber grades (MSR & MEL) are available for use with the ANSI/AWC NDS-2015, 2018 and 2024 and the CSA O86-2014 design codes. Older versions of the design codes will not support design of mechanically graded materials from the program databases. However, you can always enter the properties as a Custom Wood Material to get the design calculations for these materials in older code versions.

Click on image to enlarge it

In order to assign a mechanically graded lumber material, you must select both the species and then the mechanical (MEL or MSR) grade. The species selection determines the shear capacity and compression perpendicular to grain capacity design values.

See Footnote #2 from NDS 2024 Table 4C which says that all species from NDS 2024 Table 4A are applicable. See clause 6.3.2 from CSA O86-14 which says that specified shear strengths shall be taken from CSA O86 Table 6.3.1A.

The other design values are defined per the mechanical grade. See NDS 2024 Table 4C and CSA O86-14 Tables 6.3.2 and 6.3.3.

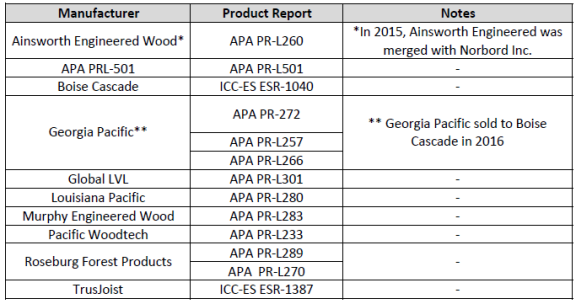

Structural Composite Lumber (SCL)

Each SCL manufacturer has documentation of their proprietary material design values. Because these are updated so often, RISA relies instead on the design data from approved product reports (APA and ICC-ES) to build the material databases:

Footnote Limitations:

Each of the above reports includes tables with design values which were used to create the RISA SCL design property material databases. However, due to the difficulty of design variation, the following limitations are present:

- The Fb design values are not factored in accordance with the depth of the member. Currently, RISA always uses the single tabular Fb value regardless of member size.

- The Ft design values are not factored in accordance with the length or thickness of the member. Currently, RISA always uses the single tabular Ft value regardless of member size.

- The Fb design value will be increased by 4% if the member is designated as a repetitive member using the Cr check box on the Wood tab of the Members Spreadsheet.

Alternatively, you can always enter the appropriate design values, per the applicable footnotes, as a Custom Wood Material.

Design Values

The design properties may be verified by clicking the  (ellipsis) button next to the Material section of the specific member's information in the Property panel.

(ellipsis) button next to the Material section of the specific member's information in the Property panel.

Click on image to enlarge it

Click on image to enlarge it

The values are as follows:

- Fb - Bending Stress Limit

- Ft - Tension Stress Limit

- Fv - Shear Stress Limit

- Fc - Compression (Parallel to Grain) Stress Limit

- E - Modulus of Elasticity

- COV_E - Coefficient of Variation in Modulus of Elasticity per NDS Table F1. This value is used in the Emin calculation. For SCL materials COV_E always equals 0.10.

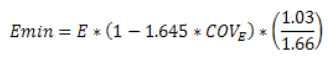

NDS Emin Calculation

RISA will calculate the Emin value for NDS wood materials rather than read it in from the design tables. In the 2024 edition of the NDS, Emin is calculated per equation (D-4) from Appendix D.

COV_E (the coefficient of variation in modulus of elasticity) comes from Table F1 in Appendix F.

-

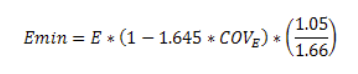

If your member is a glulam or SCL material, the Emin equation becomes:

Note

Currently, the program only designs using the Joist properties of the SCL materials. This assumes that the loading is always on the small dimension side of the member. In a future version we will be taking the Plank values into consideration as well. In the meantime you can always enter the appropriate design values from these tables as a Custom Wood Material for use in your model.

Custom Wood Sizes

If you would like to enter explicit dimensions of a member or if the member is "Not Dressed", the member must be designated as a "Full Sawn" member by choosing Net Rectangular as the Shape Type and entering the exact dimensions. This applies to regular wood species, custom wood species, Structural Composite Lumber (SCL) and Glu-Lam members.